INERATEC produces ASTM-conform Sustainable Aviation Fuel (SAF)

2 x Word2 x PDF3 x JPGDownload

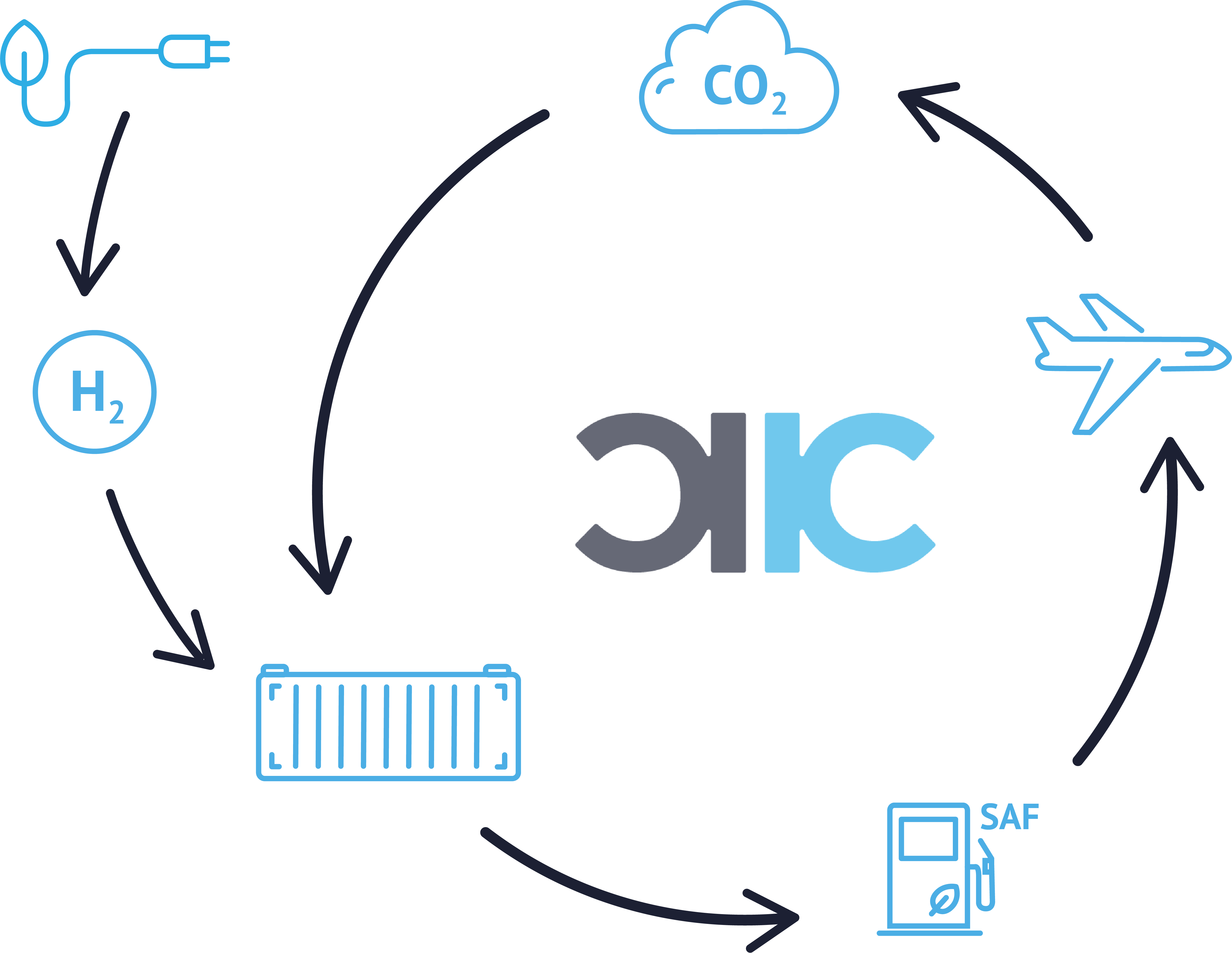

Test results from the German Aerospace Center (DLR) as part of the "PowerFuel" project have confirmed that drop-in capable synthetic kerosene can be produced in a power-to-liquid plant from INERATEC in accordance with the requirements of ASTM 7566 and used blended as JET A-1 fuel. This marks a milestone in the development of the value chain of "Sustainable Aviation Fuel" (SAF) from CO₂ and hydrogen. The fuel was produced in collaboration with the Karlsruhe Institute of Technology (KIT).

Drop-in eSAF can be produced from CO₂ and green hydrogen - this has been confirmed at the Karlsruhe Institute of Technology (KIT) site with the operation of a power-to-liquid (PtL) plant by INERATEC. The requirements for eSAF are the highest among e-Fuels in terms of fuel quality as well as placing on the market. This milestone was achieved as part of the "PowerFuel" project (FKZ 03EIV071) funded by the German Federal Ministry of Economics and Climate Protection, as well as the "Kopernikus P2X" funding project (FKZ 03SFK2D1-2) funded by the German Federal Ministry of Education and Research.

"We are "first-to-market" with our synthetic kerosene."

"To meet the demand for e-SAF in aviation and to fulfill the quotas according to the specifications, INERATEC is working on the implementation on a large industrial scale in a variety of projects," explains Dr.-Ing. Tim Boeltken, CEO of INERATEC. "Starting in 2024, we will produce up to 2,500 t of sustainable e-Fuels annually at our pioneer plant in Frankfurt Höchst, which is currently the world's largest. With this and many other plants, we will make a significant contribution to reducing CO₂ emissions in the aviation industry in the future."

The starting material for kerosene production is a synthetic crude (a synthetic crude oil substitute). After processing by so-called "hydrocracking" (a splitting of the long-chain crude into the corresponding fuel fractions) and an isomerization step to improve the cold flowability under flight conditions by KIT, the kerosene was analyzed. Key analytical results show that paraffinic kerosene produced from hydrogen and CO2 can be blended according to ASTM 7566 and used as Jet A-1 in aviation. The amount of CO₂ required to produce the SAF is equal to the amount emitted during combustion in the aircraft. Flying thus becomes CO₂-neutral. In addition, previous tests have already shown that burning sustainable aviation gasoline with a low aromatics content can lead to a 50 to 70 percent reduction in soot and ice particle concentrations compared to conventional kerosene.* This means that this reliable sustainable alternative to fossil kerosene can make a significant contribution to implementing the German government's PtL roadmap.

Kontakt

INERATEC GmbH

Isabel Fisch

Communication & PR Manager

T: + 49 1621852663

E: isabel.fisch@ineratec.de