UP TO 300 T/A

INERATEC PtL 200 S

PLACE REQUIREMENTS | (excl. compressor) | approx. 21 m x 17 m |

PRODUCTS |

| Fischer-Tropsch oil |

PRODUCTION QUANTITY |

| up to 40 kg/h |

ROUGE MATERIALS | H₂ | up to 20 kg/h |

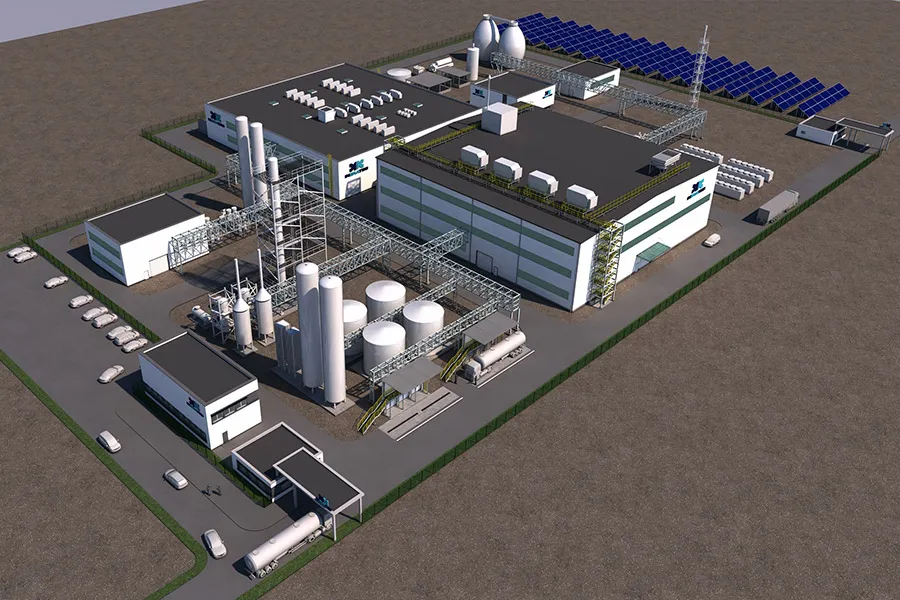

UP TO 1,500 T/A

INERATEC PtL 200

PLACE REQUIREMENTS | (excl. compressor) | approx. 35 m x 18 m |

PRODUCTS |

| Fischer-Tropsch oil |

PRODUCTION QUANTITY |

| up to 200 kg/h |

COARDS | H₂ | up to 100 kg/h |

How to get your system

CONTACT US

Define plant type and size

Our technology is modular and scalable. This means that our systems can be tailored and designed to meet your needs

Production of the plant

We build your plant. At our site in Karlsruhe. Made in Germany.

Maintain and commission the plant

From the idea to the ramp-up of production, we accompany you through all phases of a project.So that you can produce the desired quantities of e-Fuel.