INERATEC's Gas-to-Liquid (GtL) plants convert synthesis gas into synthetic hydrocarbons. The synthesis gas - usually consisting of hydrogen and carbon monoxide - is converted in Fischer-Tropsch reactors. The plants are designed for different synthesis gas sources, either from biogenic, industrial or other power-to-X processes. As these sources differ in terms of composition, gas quality and inert gas content, the plant design, process control and resulting performance data vary depending on the project.

The following technical specifications and economic key figures are based on a defined reference synthesis gas composition. Deviating gas qualities and customer-specific requirements are taken into account during project planning.

INERATEC GtL 200 S

MODUL |

| 200 S |

PRODUCTS |

| Fischer-Tropsch oil |

PRODUCTION QUANTITY |

| up to 40 kg/h |

ROUGE MATERIALS | Synthesis gas | up to 130 kg/h |

INERATEC GtL 200

MODUL |

| GtL 200 |

PRODUCTS |

| Fischer-Tropsch oil |

PRODUCTION QUANTITY |

| up to 200 kg/h |

RESOURCES | Synthesis gas | up to 650 kg/h |

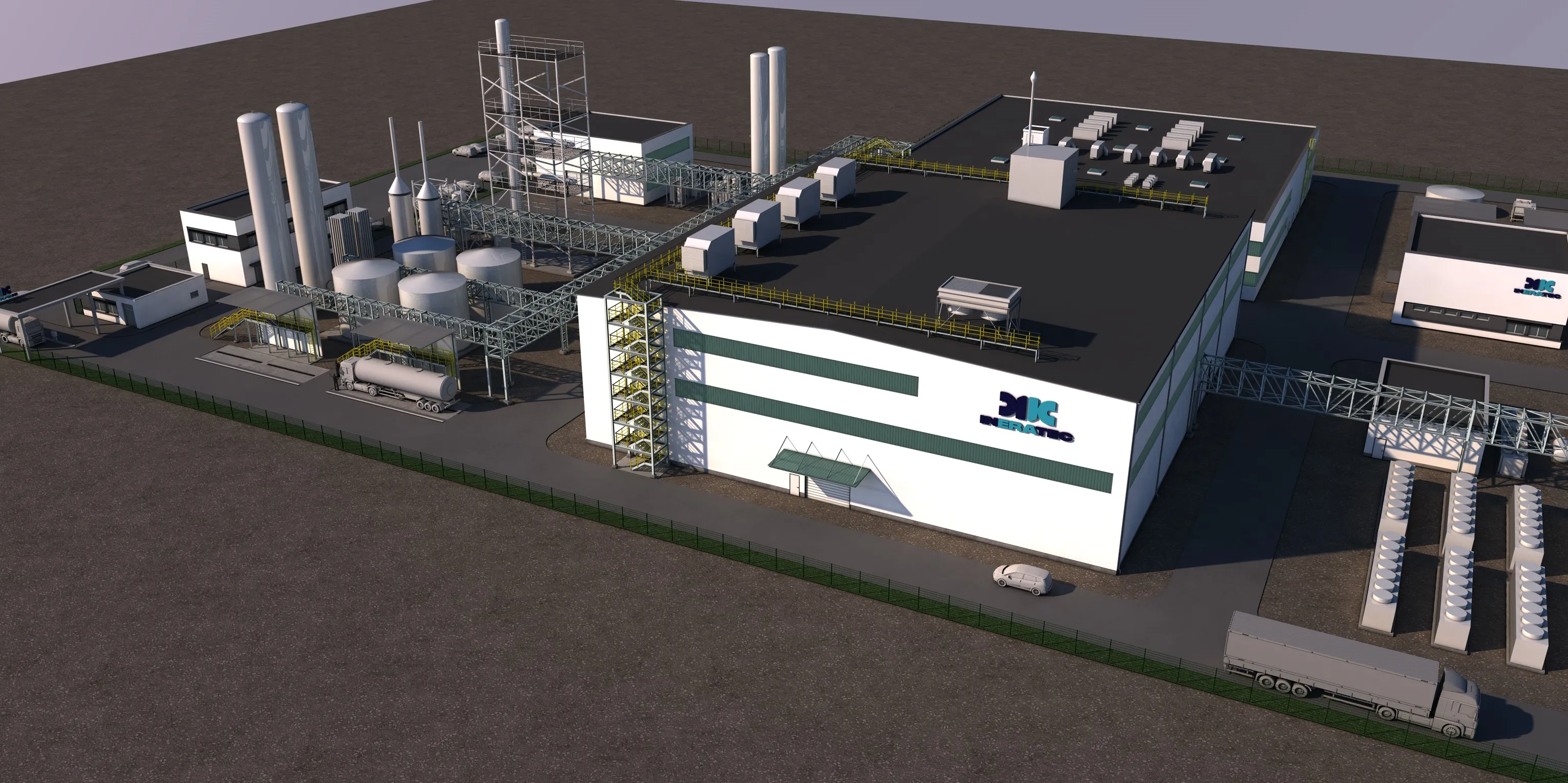

INERATEC GtL 5000

How to get your plant configuration

CONTACT US

Define plant type and size

Our technology is modular and scalable. This means that our systems can be tailored and designed to your needs.

Production of the plant

We build your plant. At our site in Karlsruhe. Made in Germany.

Maintain and commission the plant

From the idea to the ramp-up of production, we accompany you through all phases of a project.So that you can produce the desired quantities of e-Fuel.